It's zinc and "cloudy"?

Zinc Plating can be clear, yellow, black, olive drab, RoHS compliant or not. It can even have no supplementary treatment or a phosphate treatment.

In other words... It's zinc and "cloudy"?

We get a lot of questions from customers on the meaning of the Types and a lot of quotes and PO's that have more questions than answers.

So let us help clear up the color and Type confusion!

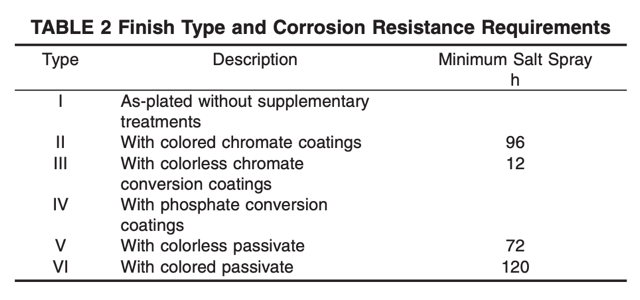

See the Table below from ASTM B633. It defines the Type of post treatments for zinc plating. Type I has no post treatment and is hard to handle. This should only be used for parts that are getting painted or oiled or better yet, never! You'll hate working with it. Type IV is a zinc phosphate and is designed to work as a paint base. Very specific and like Type I, not a good stand alone process.

The Types that we often see, Types II and III, are hexavalent processes and are NOT RoHS Compliant. They still call these chromates as they are hex chrome based.

TDF offers these for our aerospace and defense customers. Type II is usually yellow although this is where olive drab and black can be used. Any, as the spec says, "colored chromate" meets Type II so be sure to specify a color in your PO or quote. Type III is "colorless" or clear so that is well... clear.

Types V and VI? Well now we're talking! At least if RoHS compliance is required. And it usually is. These "passivates" as we call them (don't get confused with passivates for stainless steel!) do not contain hex chrome and are RoHS compliant, meet the MIL Spec, and come in Type V clear and Type VI iridescent yellow or black.

And TDF does a fantastic Type VI RoHS compliant black zinc! Jet black, uniform, durable and decorative, our RoHS compliant zinc and black is a sight to behold!

So for any of your zinc needs, Types I - VI, with or without Hydrogen Embrittlement bakes, commercial, aerospace or defense related, we're here to help!

Call us 1st! We'll answer your questions sure but, more importantly, we tell you what you need to know! Thank you!