Experience Our Exceptional Services

Join us on an outstanding journey with our tradition based, technology driven metal finishing company. Let's develop your requirements into reality, turning your vision into World Class products.

We understand the importance of personalized, top-tier customer service. Your satisfaction is our priority, ensuring that every step of the way, we exceed your expectations.

PROCESSES WE OFFER

Anodizing Type II Conventional Anodizing

Anodized Aluminum Type II Class 2 Dyed - Black, Red, Green, Blue, Gray

Hard Anodizing - Type III

Hard Anodize with Teflon Post Treatment

Black Chemical Film - Copper Oxide Ebonol

Black Oxide - Class 1 on Steel

Black Passivating - Class 4 on Stainless Alloys

Black Phosphate - Zinc Phosphate

Bright Dipping of Copper

Etching of Stainless Steel

Titanium Cleaning and Etching

Descaling / Pickling of Nickel Alloys

Passivating Stainless Steel - All Alloys and Types

Bright Nickel - Decorative Nickel

Sulfamate Nickel - Engineering Nickel

Bright Tin / Matte Tin

Cadmium - With Chromates Including Olive Drab

Caustic Etching

Chromating (Chemical Film)

Copper

Electroless Nickel

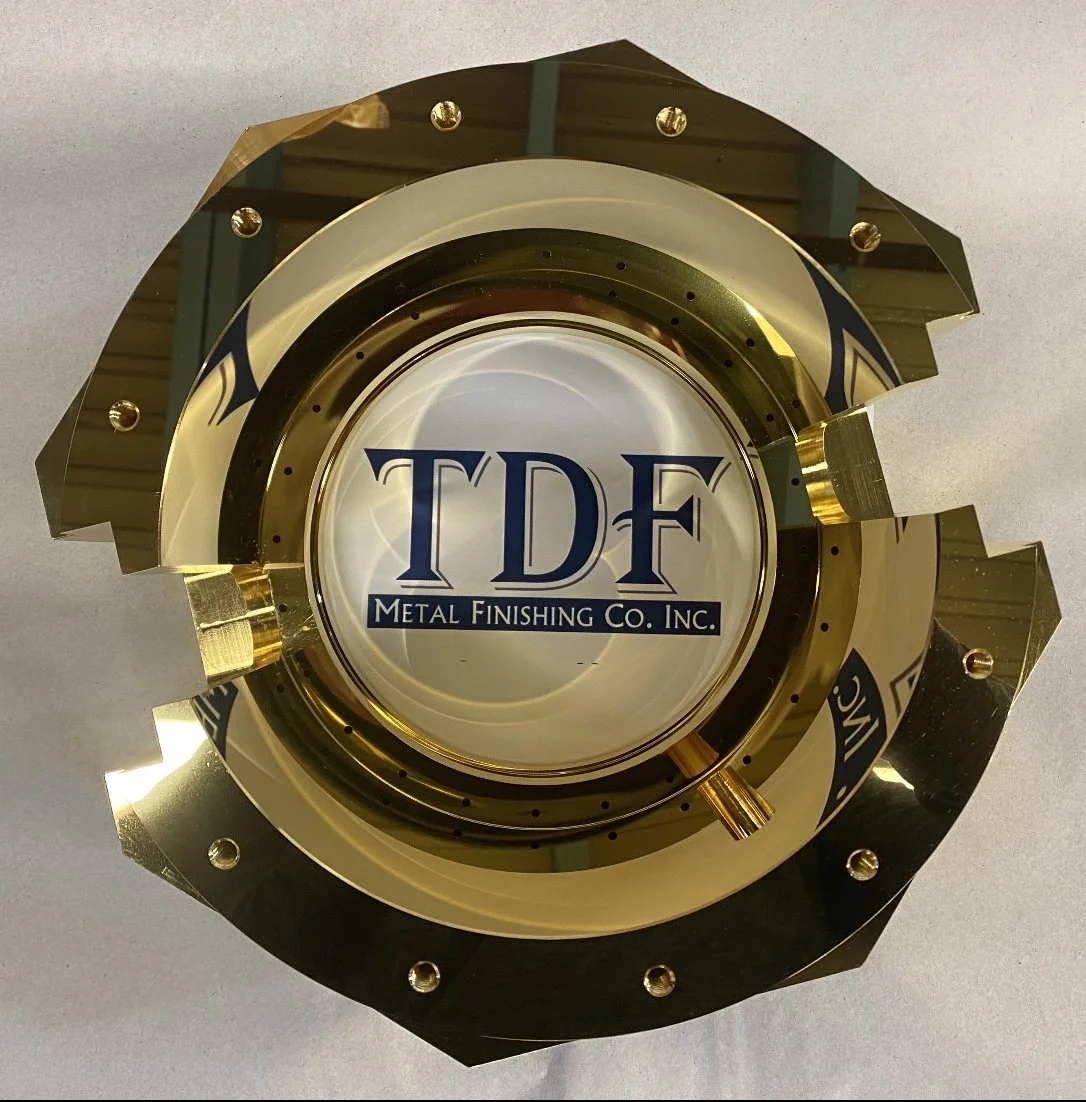

Gold Plating

Silver Plating

Zinc Plating

Sandblasting

Masking to Meet all Requirements.

FINISHES

In House Testing Capabilities / Solderability / Salt Spray Corrosion Testing | 24 Hour Humidity | X-Ray Fluorescence Thickness Testing |