The Perfect P.O

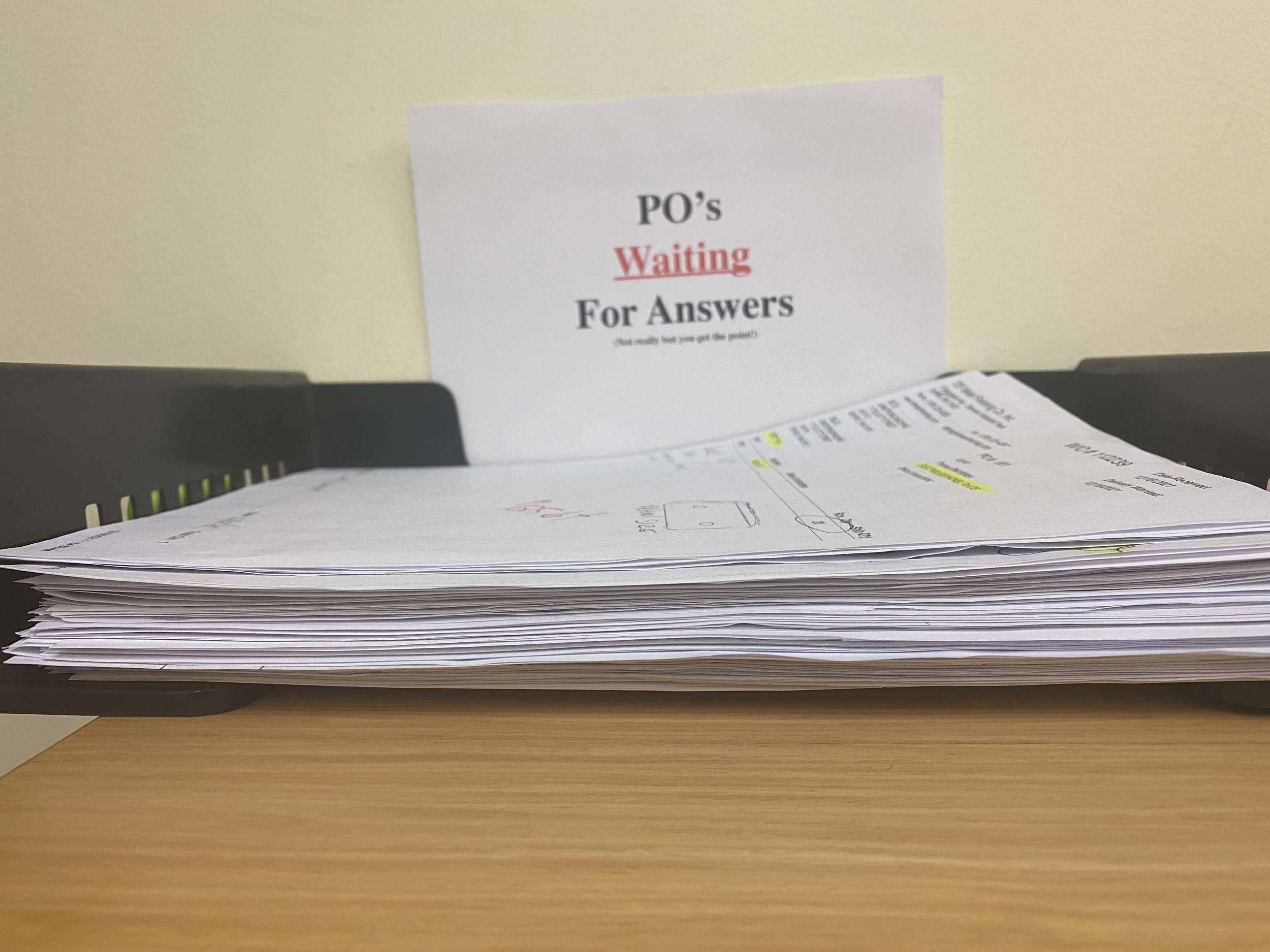

Your PO to your metal finisher is step 1 to success and speed! So much so that you may have seen or heard about “The Perfect PO” in other places and pages.

Wait… key to success and speed? How on earth is a piece of paper the key to success? How is a key to speed? Well… It’s critical to both and here’s why.

When a part is machined or fabricated do you as the machinist or fabricator know what alloy or material you are working with? Do you ever order “aluminum” from your metal supplier? Do you ever make a part without a blueprint with the dimensions and description? Of course not. To a plater your PO is where we start when it comes to the finish. Alloys and material are critical. What we do to 6061 will ruin 2024. 7075 needs a critical anodizing process adjustment or it will be junk and quick. Or at least make it uglier than it needs to be.

If CRS is treated as stainless we can create a giant orange cloud that develops as your part dissolves in the wrong acid. If we treat stainless as CRS in plating that nickel plated part that you desperately needed to ship to your customer is instead sitting in a stripping solution to remove the nickel that was coming off in sheets because we pretreated it wrong. And we are fairly confident that the part won’t get ruined in the strip.

And, copper is copper right? Unless it’s beryllium copper and heat treated which means it may blister when plated or have visible scale on it that makes it look horrible when plated. And if it’s a copper alloy it’s easy to mistreat the material removing the tin from bronze and the zinc from brass making your part look more like the surface of the moon that that 32 RMA finish you sent it to us with. Or worse.

And don't get me started with tellurium copper. You know how I found out how to plate tellurium copper? I paid for the parts I ruined and vowed to never to do that again. The only way to learn is the hard way. Or... Listen and learn from your favorite plater who has your best interests in mind. A plater that has pretty much ruined every base material known to man. Sometimes because we screwed up.

And sometimes because a customer led us down the path to disaster. Usually at the worst possible time on absolutely the wrong rush job for the most critical customer.

- Better Ask Marko