Quality

TDF is an ISO 9001 Certified company. Click HERE for a copy of our Certification.

In addition to our Chemical Analysis Lab, our Quality System is ISO Certified and helps us assure that your parts are delivered to meet the expectations and certifications you require.

Our skilled operators are highly trained and our team of inspection personnel assure that the thickness measurements are accurate, the critical baking requirements have been met and the additional dimensional, masking and racking criteria has been satisfied. It’s Quality 1st and foremost and Quality again as the parts are shipped.

Quality starts at Incoming Inspection and our receiving personnel are trained to review purchase orders, specifications and any special instructions you have passed along to us.

Our job process sheets have detailed instructions and can include any requirements or instructions you would like us to follow. Our operators document each step of the operation ensuring attention to detail and process instructions. TDF also maintains calibrated and standardized measuring equipment for every process we offer and all the Quality tools and equipment we use. You can be sure that your coatings and our equipment has been calibrated, measured and verified.

LATEST CERTIFICATIONS

This important Aerospace Accreditation will allow us to do even more of the aircraft, defense and aerospace work needed by many in our customer base. With many waivers and approvals, TDF its currently doing the high tech, advanced work required by these industries and NADCAP will certify us as a more complete aerospace finisher.

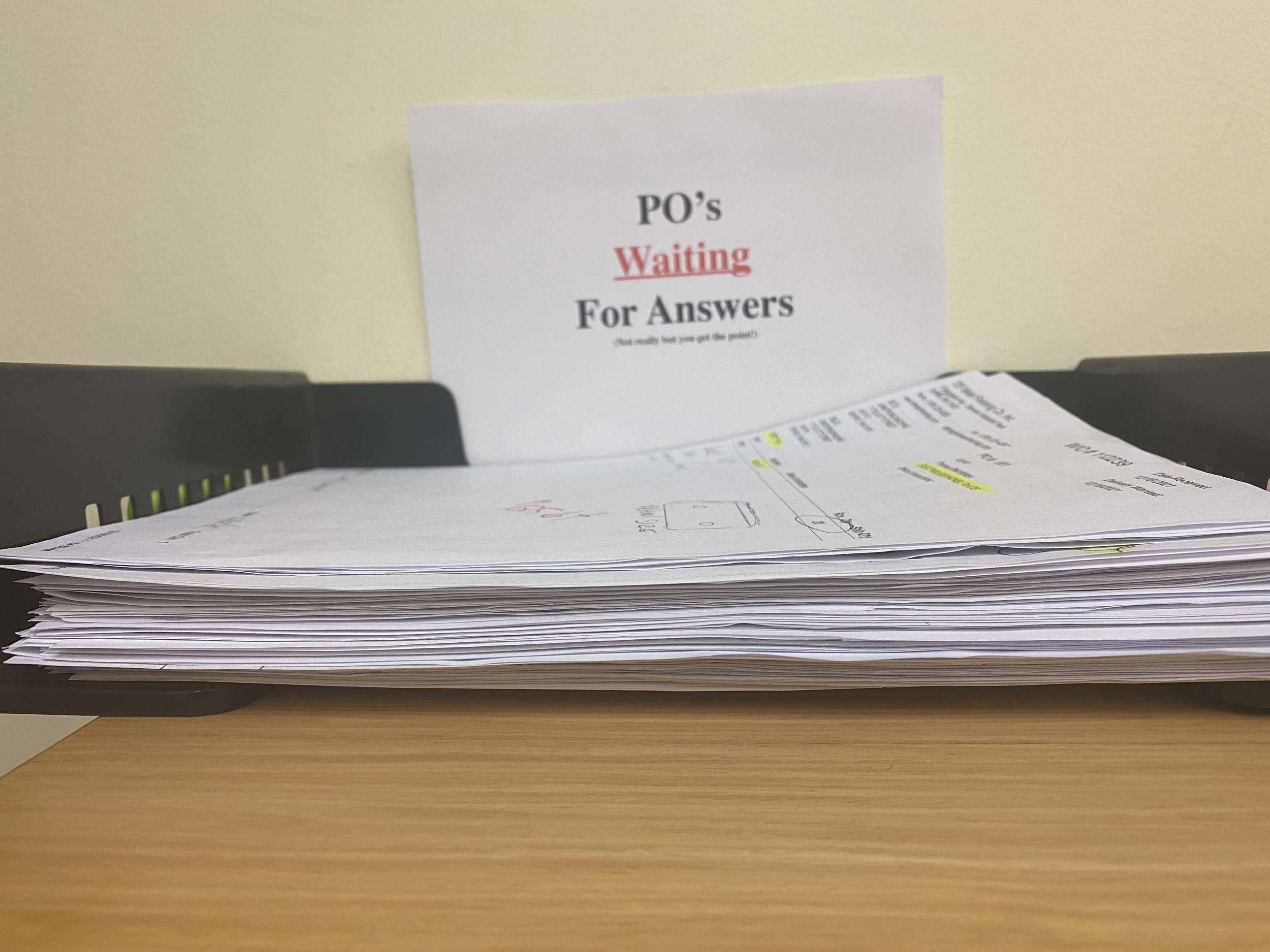

Watch for an upcoming announcement on the finalization of our new Job Processing Software. This state of the art system will help TDF manage every aspect of our process, inspection and scheduling. A special portal for customers will allow you to log in and see the status and expected delivery date for any and all of your orders. PO’s will be able to be downloaded into our system and a lot of your specific customer information will be available to you just by logging on.

So again, it’s Quality 1st and foremost throughout our facility and at every step in the process. Our culture, visibly evident in every member of our team, is to expect and accept only the best in ourselves, our services and in the way we work with our customers, helping you to be at your best when it comes to finishing.

Process Specifications

| Description | Specification / Latest Revision |

| Anodize | MIL-A-8625 Type II |

| Hard Anodize | MIL-A-8625 Type III |

| Black Oxide | MIL-C-13924 Class 1, AMS2485 |

| Black Passivate | MIL-C-13924 Class 4 |

| Cadmium | QQ-P-416, AMS2400 |

| Chemical Film | MIL-C-5541, ASTM-B449 |

| Chemical Finish, Black | MIL-F-495 |

| Chemical Passivation | ASTM-A967-96 |

| Cleaning, Descaling, and Passivation | ASTM-A380-96 |

| Copper | MIL-C-14550 |

| Electroless Nickel | AMS2404 |

| ElectroNickel and Gold | QQ-N-290/MIL-G-45204 |

| Gold, Electrodeposited | MIL-G-45204 |

| Hard Anodize | MIL-A-8625 Type III |

| Nickel | QQ-N-290 |

| Passivate | QQ-P-35/MIL-S-5002 |

| Phosphate Coating: Heavy | DOD-P-16232 |

| Phosphate Coating: Light | TT-C-490 |

| Rhodium, Electrodeposited | MIL-R-46085 |

| Silver, Electrodeposited | QQ-S-365 |

| Silver (Nickel Strike, High Bake) | AMS2410 |

| Silver (High Temperature Applications) | AMS2411 |

| Tin | AMS2408 , MIL-T-10727/ASTM-B545 |

| Zinc | AMS2402, ASTM-B633 |

Customer Satisfaction Reviews

(Blind Survey) – 16/66 responses (24.24%)

CUSTOMER FEEDBACK:

Customer 4: Very consistent; People respond and answer questions when asked; respond well to rush jobs.

Customer 7: The invoices are not always clear as to the charges.

If they could be broken down by unit prices and any fees (Hazmat Fee for example) that would help.

Customer 9: Great communication and always willing to make sure orders are accurate and on time.

Customer 13: Always professional and wrapped with care; Time of completion is always within a couple days of dropping off. We are very satisfied with how everything is going so far. Cannot ask for much more!

Customer 14: Great Folks!